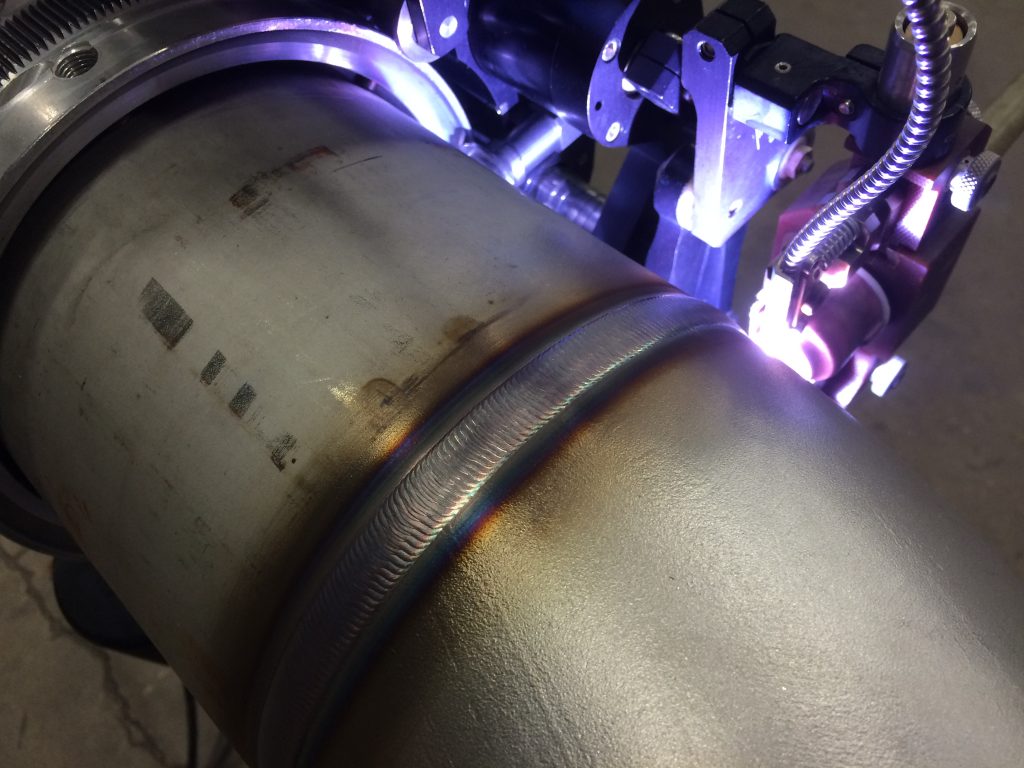

High-Purity Orbital Welding

Using state-of-the-art orbital equipment, we can handle all of your custom fabrication needs. Our clients span a wide variety of industries that count on having high-purity, contaminant-free systems: semi-conductor, food and beverage, dairy, pharmaceuticals, brewery, and personal care.

Advantages of High-Purity Orbital Welding:

Consistent quality: The computer-controlled process ensures that each weld is of the same high quality, reducing the risk of defects or contamination.

High precision: The high-purity orbital welding process provides precise control over the weld, resulting in accurate and repeatable welds.

Cleanliness: The process is performed in a cleanroom environment, which ensures that the weld is free of contaminants and meets the highest standards of purity.

Efficiency: The automated process reduces the time and labor required for welding, increasing efficiency and reducing costs.

Our Process Ensures High-Purity Weld Quality:

Planning: Our experienced technicians work closely with you to understand your specific needs and requirements, including the materials to be welded and the specifications for the weld.

Preparation: We prepare the workpiece and equipment for the welding process, ensuring that they are clean and free of contaminants.

Welding: We use our state-of-the-art orbital welding equipment to perform the high-purity weld, closely monitoring the process to ensure accuracy and consistency.

Inspection: Our quality control specialists perform visual and non-destructive testing to ensure that the weld meets the highest standards of quality and purity.

Documentation: We provide detailed documentation of each weld, including material certifications, inspection reports, and other relevant information.

Explore Other Capabilities

- Industrial General Contracting

- 3D Scan/Design

- Project/Construction Management

- Plant Layout in 3D CAD

- P&ID / Plant Spec

- Shop Pre-Fab

- Process/Utility Piping

- Tanks/Pressure Vessels

- Structural Steel Fab/Install

- Skid Design/Fab

- Plant Relocation/Equipment Setting

- High-Purity Orbital Welding

- Civil/Site Work

- Plumbing

- Underground